How to Use a Refractometer

Testing the Refractive Index of Listed Antifreeze

Listed antifreeze solutions address important life safety concerns associated with unlisted fluids and, like all systems, must be properly inspected, tested and maintained to ensure optimal safety and performance.

A key difference in the inspection, testing and maintenance (ITM) of a listed product like freezemaster™ antifreeze is the process and tools used. A freeze point (temperature) test is no longer sufficient. One test that can identify small changes in listed antifreeze from dilution is a refractive index (RI) test. Not all listed antifreeze brands can be tested using a refractometer; some must be tested using a hydrometer. freezemaster™ antifreeze may be tested using either tool.

For many contractors, a refractometer is a new tool, but these tips can help you quickly learn to use one.

What is Refractive Index?

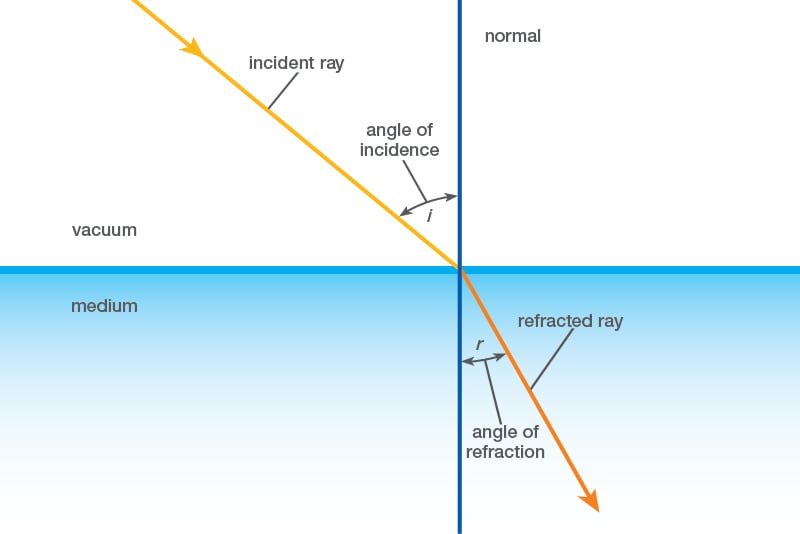

Refractive index is a measurement of light refraction, or the bending of light as it travels through an object. It’s basically a geometry problem: As light penetrates an object and bumps into its molecules, it changes directions. These angle changes (Ө) are used to calculate the index of refraction. This is why a drinking straw in water appears to be bent when looked at through the glass.

The refractive index is a ratio representing the angle of refraction. Refractive index is a useful testing tool because a liquid can have a known refractive index; deviation from that refractive index can indicate problems or changes.

What is a Refractometer?

A refractometer is an optics instrument that provides a refractive index value for a material. They pack accurate, straightforward science into a simple instrument. By testing a liquid’s refractive index (RI), a refractometer confirms that the liquid hasn’t thickened or been diluted. The basic components of a refractometer are a light source, a reference prism and a detector.

Refractometers are an essential tool for testing factory-premixed, UL listed antifreeze to ensure that the product is performing as designed and can continue to help save lives and property.

Choosing a Refractometer

There are two basic options for refractometers: tabletop and handheld. The tabletop Abbe device offers excellent resolution but is not portable. A handheld manual or digital refractometer is portable, more reasonable in price and accurate to +/- 0.0003. They are the most popular for field use.

Handheld refractometers are best known for providing the BRIX level, reported as ºBx or % sugar content of various foods and beverages. Although the BRIX scale is correlated to the refractive index, only RI is used to test listed antifreeze. Do not use BRIX, glycol or glycerin scales to test listed antifreeze.

Testing Listed Antifreeze with a Refractometer

The following guidelines are generally applicable, but always follow the refractometer manufacturer’s and listed antifreeze manufacturer’s instructions.

You’ll need:

- A container to hold drained antifreeze for testing

- Thermometer

- Unused droppers or pipettes

- Installation manual for the listed antifreeze brand

- Refractometer

Basic steps to test listed antifreeze with a refractometer:

- Clean and dry your refractometer before use. Residual antifreeze or water will change the results. Rinse the well with deionized or distilled water as tap water has variable quality that can affect readings.

- Inspect the pipes and hang tag.

- Shut off the water source and drain a half gallon of antifreeze from the most remote part of the system. You may need to pull multiple samples if the system is large and covers areas with stark temperature differences.

- Calibrate the device in the testing environment to bring both the device and the testing fluid to about the same ambient temperature.

- Use a dropper or pipette to add listed antifreeze to be tested into the well, ensuring that the sight glass is covered.

- If the sample tests in specification, replace the drained antifreeze and update the hang tag.

- If the sample tests out of specification, follow NFPA standards for a full system drain, flush and replacement.

The RI will be reported as a unitless number at a particular temperature, or autocorrected to 20ºC, often shown as “nD20”. The refractive index is always reported at a particular temperature because RI changes with temperature. The colder your antifreeze is when measured, the higher the RI, and vice versa.

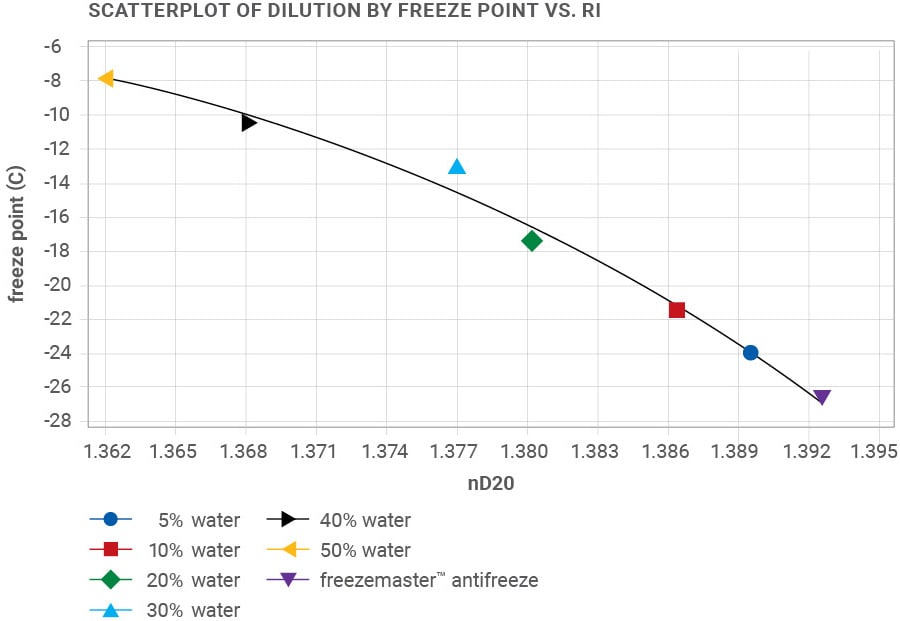

Listed antifreeze, like freezemaster™ antifreeze, is never to be purposely diluted with water. Diluted listed antifreeze is considered out of specification and must be drained and replaced. The chart below shows the freeze point and RI of freezemaster™ antifreeze as diluted with water at varying percentages and measured with a laboratory-grade Abbe refractometer at 20ºC. The corresponding freezing points (ASTM D6660 method) are also shown below.