Freeze Protection Plus: Four Factors for Choosing the Right Listed Antifreeze for Fire Sprinkler Systems

Most antifreeze sprinkler systems now incorporate listed antifreeze, as it has proven to keep those critical systems safely functioning at optimal levels.

However, there is still a bit of confusion around the benefits of listed antifreeze, what product to select and the impact on installation and maintenance.

A UL listing means the antifreeze product has met the highest standard in safety and performance. UL 2901 requires fire performance (flammability), hydraulic characteristics, marking and installation specifications. Also, per UL 2901, listed antifreeze must:

- Meet minimum temperature requirements: A product will be listed for the lowest temperature at which it remains in a liquid state and allows water to flow in the event of fire, plus a safety factor.

- Meet minimum corrosion protection: Premixed antifreeze solutions must not cause the corrosion to exceed 1.0 mils/year (0.025 mm/year) per ASTM A108, Grade 1010 steel; ASTM B16, H02 (Half Hard) brass; or Type 304 stainless steel, among other metallic materials that might be used in sprinkler applications with antifreeze.

- Be factory-premixed: UL 2901-listed antifreeze solutions are premixed at a manufacturing site and are not intended to be diluted.

Choosing whether to switch to a listed antifreeze is the easy part – it’s worth it and is required by code in most cases. But deciding which antifreeze to choose can be more challenging. It may seem tempting to focus only on minimum temperatures. But like sprinkler heads, listings and design parameters vary among antifreezes. Here are four issues to consider:

1. System Volume Size Limitations

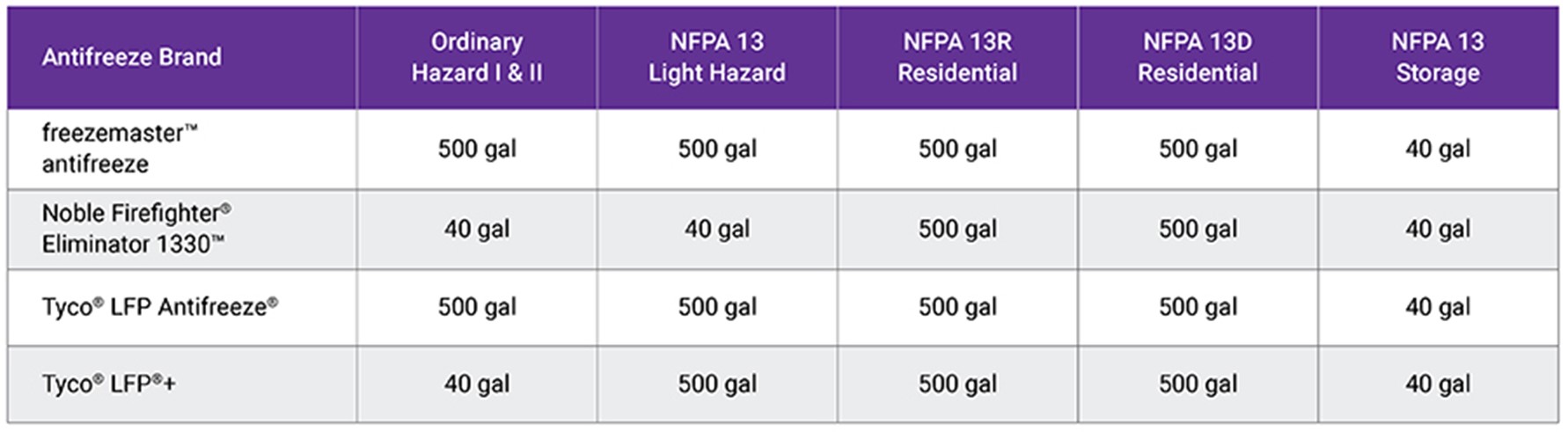

Volume limitations vary widely between products, and for each product, between hazard uses. To perform as expected in a fire, UL-listed antifreeze products should not exceed their volume listing.

While currently available listed antifreeze products are identical for NFPA 13R and 13D Residential and NFPA 13 Storage applications, they differ on Ordinary Hazard I & II and NFPA 13 Light Hazard applications. Those with large systems should assess the costs of valving the system off to meet volume limitations of a listed antifreeze product.

It's not recommended to use an antifreeze outside of its listing, but a recent update to the 2023 edition of NFPA 25 allows you to do so when replacing unlisted antifreeze in an existing system, as long it provides adequate freeze protection. If you want to use a listed antifreeze outside its specific listing requirements, it’s highly recommended you work closely with your local Authority Having Jurisdiction (AHJ) to determine safe and acceptable use.

2. Minimum Design Pressure

The colder temperatures get, the more viscous antifreeze solutions become, which may not protect the farthest-point sprinklers adequately. When antifreeze thickens it moves a shorter distance for a certain pressure, which means it may provide less protection. To overcome this, some listed antifreeze products require a minimum design pressure to ensure that the solution is adequately delivered to the most remote sprinkler head if there is a fire. Design pressure is typically specified in NFPA 13 and can be based on the size and layout of the building and hazard type. Minimum design pressure requirements for listed antifreeze may also mean additional maintenance and equipment to stay at the proper pressure. freezemaster™ antifreeze does not have a minimum design temperature other than that of the sprinkler head, unlike some competing listed antifreezes, which have a minimum design pressure of 20 psi at the most remote sprinkler head.

3. Compatibility with Piping Types and Other System Materials

Piping material compatibility is another important consideration when evaluating listed antifreeze. To avoid damage or a costly repiping project, compare a product’s listing with a system’s piping material.

The UL 2901 Standard includes compatibility testing with most sprinkler system accessories such as materials you'd find in valves and sprinkler head adapters, as well as piping materials. In terms of piping materials, all listed antifreezes are listed as compatible with black steel, stainless steel, brass, copper, bronze, cast iron, PEX, and CPVC. However, only freezemaster™ antifreeze is listed for use with galvanized steel. If "galvanized steel" is not specifically listed in the compatibility section of the antifreeze's tech data sheet, either the antifreeze did not complete the additional compatibility testing required for galvanized steel or the antifreeze did complete the additional testing but failed the test. Key point: if it’s galvanized, your only option is freezemaster™ antifreeze.

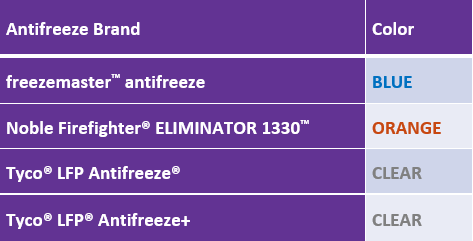

4. Product Color

There's a variety of listed antifreeze colors, and while the formulas may have some similarities, there are notable differences in how the colors contribute to the ease of installation and maintenance.

Clear antifreeze is the same color as water, and orange antifreeze looks similar to rusty water. freezemaster™ antifreeze has a blue tint, helping technicians easily see it as it exits the drains when flushing and filling the system or spot if it has been diluted with water. Plus, technicians won't need to rely solely on testing instruments to identify a fully flushed or filled system.

Choose the Best Listed Antifreeze for Your System

freezemaster™ antifreeze makes it easier than ever to make the switch to listed antifreeze and to be in full compliance with NFPA requirements. It’s a small change that can make a big difference.

Our team of experts is available to help answer any questions and determine if freezemaster™ antifreeze is right for your sprinkler system.