Simplify the Switch to Listed Antifreeze

Fire protection contractors are on the front lines of defense for keeping people safe from fires. That’s why NFPA standards specify factory premixed, listed antifreeze for fire sprinkler systems. This investment in life-safety is a necessity, but it doesn’t have to be complicated. In fact, switching to a listed antifreeze has never been easier. You’re in the right place to learn everything you need to know about listed antifreeze, why UL-listed freezemaster™ antifreeze is the superior choice, and the basics of a successful installation.

NFPA Compliance

In the last decade, a number of high-profile fires were significantly worsened by the unlisted freeze-protection fluids in fire sprinkler systems, resulting in injuries and deaths. To better protect lives,  . Unlike unlisted fluids, factory-premixed antifreeze will always have the correct formulation and will avoid the explosive potential of an unlisted mixture.

. Unlike unlisted fluids, factory-premixed antifreeze will always have the correct formulation and will avoid the explosive potential of an unlisted mixture.

New and existing antifreeze fire sprinkler systems must function so that the antifreeze in the system does not dilute. This may require some rework of existing systems like  tank per NFPA 13 guidelines.

tank per NFPA 13 guidelines.

Why freezemaster™ Antifreeze?

As the listed antifreeze market grows, freezemaster™ antifreeze has become the most popular product for many reasons. Beyond excellent fire sprinkler system freeze protection, here’s why so many installers are choosing freezemaster™ antifreeze.

freezemaster™ antifreeze is colored blue for easy visual identification

While some other listed antifreeze products and unlisted fluids are clear or the color of rusty water, freezemaster™ antifreeze’s blue color lets you see the solution as it exits the drains when flushing and filling the system during antifreeze installation and maintenance. You can literally see the freezemaster™ antifreeze advantage!

freezemaster™ antifreeze is listed for use in large systems.

Part of an antifreeze's listing includes system size volume limitations. For example, some antifreeze solutions are not listed for use in systems larger than 40 gallons, causing contractors to have to valve off the system every 40 gallons to be compliant. freezemaster(TM) antifreeze eliminates this tedious process because it is UL listed for use in light hazard systems up to 500 gallons and Ordinary Hazard 1 and 2 systems up to 500 gallons.

Learn more about freezemaster antifreeze's listing here.

freezemaster™ antifreeze is the easiest listed antifreeze to implement in a retrofit

Not all listed antifreezes are compatible with every system. freezemaster™ antifreeze is the only listed antifreeze compatible with galvanized pipe, and combined with the larger volume listing for Ordinary Hazard 1 & 2 applications, switching an existing fire sprinkler system to listed antifreeze will require few or no system modifications with freezemaster™ antifreeze. Know your system and specify the right antifreeze for that system.

freezemaster™ antifreeze is the only antifreeze listed for use with galvanized piping systems

freezemaster™ antifreeze has unsurpassed customer support.

freezemaster™ antifreeze is backed by Lubrizol and Viking, both experts in fire sprinkler systems as a whole - not just the antifreeze! Not only are our combined network of over 60 representatives across the US and Canada at your service, you can also utilize freezemaster antifreeze's helpful online resources, such as refractometer guidance and an antifreeze volume calculator.

How to Install Listed freezemaster™ Antifreeze

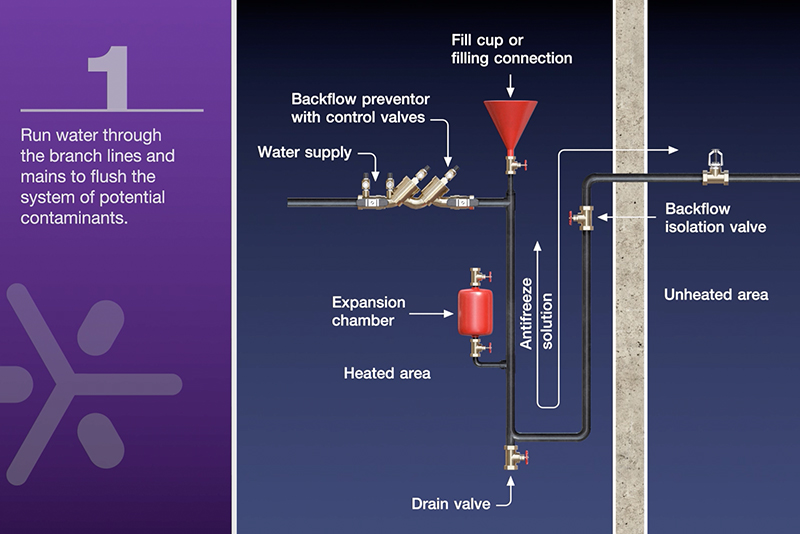

Installing freezemaster™ antifreeze in a typical antifreeze loop can be done in six steps:

- Run water through the branch lines and mains to flush the system of potential contaminants. Properly dispose of unlisted fluids flushed from the system.

- Shut off the main water valve.

- Open the drain valve and fill cup.

- Fill the loop with freezemaster™ antifreeze using your preferred method.

- Allow the system to set, then test volume and quality from the drain valve.

- Close the antifreeze cup valve and reopen the main water valve.

Each UL-listed antifreeze has its own listing requirements that vary. Always consult the manufacturer's  for installation details, testing criteria, and more.

for installation details, testing criteria, and more.