Why NFPA Requires Annual Antifreeze Testing

Have you ever wondered why antifreeze in water-based fire sprinkler systems requires yearly testing before the onset of freezing weather?

The answer: Testing ensures that antifreeze maintains its proper concentration and freeze point. For agency-listed antifreeze, as required by updates to NFPA 25, testing must confirm a 100% concentration.

More about Antifreeze Concentrations

In a wet system, antifreeze must always remain in a liquid state and address the life safety issues associated with antifreeze use. To ensure this, the concentration of antifreeze solution should always be no more than the least amount necessary for the anticipated minimum temperature.

In the event of leaks, pressure surges or temperature changes to the system, antifreeze can flow out of the system or water can flow into the system, leading to changes in the freeze temperature and antifreeze concentrations. This is especially true for existing systems that may not have an expansion tank installed and may have a hole in the check valve.

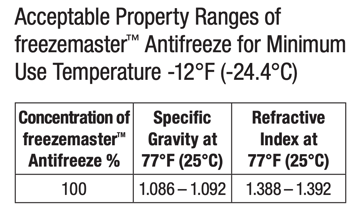

If concentration conditions deviate from allowable tolerances, the antifreeze must be replaced. When NFPA 25 was updated to require agency-listed antifreeze, manufacturers like Lubrizol had to create a new product to meet NFPA requirements. These new, factory-premixed products were sent to testing agencies like UL in a 100% concentration for testing. As such, the product is only UL-listed at 100%, the tested concentration by volume, as illustrated by the chart below for freezemaster™ antifreeze.

How to Test Listed Antifreeze

Annual testing of antifreeze in a sprinkler system is conducted by a qualified inspection, testing and maintenance (ITM) service in compliance with NFPA 25: Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems or by the local authority having jurisdiction (AHJ). Testing occurs at the most remote portion and where antifreeze interfaces with the wet pipe system. For systems over 150 gallons, one additional test point is conducted every 100 feet.

The inspector measures the specific gravity or the refractive index of the system antifreeze; either approach is acceptable for freezemaster™ antifreeze, though some other listed products require a specific testing method. Inspectors must use the proper equipment: a laboratory-grade hydrometer for specific gravity and an analog or a digital refractometer if measuring refractive index. These instruments must be calibrated at least annually to reduce the risk of incorrect test results.

After testing, NFPA requires a tag to be affixed to the riser indicating the date tested or replaced, the type and concentration by volume of fluid used, system capacity (by volume), the contractor’s name and license number and a statement indicating if the entire system was drained and replaced with antifreeze. A full drain is required if the concentration of listed antifreeze reads anything other than 100%.

A full drain, flush and refill, if needed, can be complicated or simplified by the listed product's coloring. Of the three UL-listed products, one is clear, which cannot be easily distinguished from water, and another is orange, which could be mistaken for rusty water in metal systems. The third, freezemaster™ antifreeze, is tinted blue so contractors are able to see the material as it exits the vents and drains when flushing and filling systems.

Check out "The Use of Refractometers for Listed Antifreeze" for additional guidance on using this testing tool.

For additional details about the care and maintenance of freezemaster™ antifreeze, download the Installation Guide.