When Is An Antifreeze Sprinkler System Better Than A Dry System?

In 2013, NFPA 25 changed to require agency-listed, factory-premixed antifreeze in new fire sprinkler systems, a response to some fatal, antifreeze-related explosions. A significant issue? No listed antifreeze products yet existed. For locations like attics, unheated warehouses, commercial freezers, overhead canopies, loading docks and parking garages, a dry fire sprinkler design was often the only choice for freeze protection in severely cold weather in the years it took for listed products to be developed, agency approved and available to purchase.

Now that listed antifreezes are commercially available, however, system designers have an actual choice. While dry systems can still be the right solution in some scenarios, they can have significant drawbacks in others. Let's consider the differences between antifreeze sprinkler systems and dry systems as well as three major drawbacks to a dry system.

Three Costs of Dry Fire Sprinkler Systems

NFPA 25 changes gave dry systems an advantage over antifreeze systems for the past decade. But with listed antifreeze like freezemaster™ antifreeze now commercially available, it's essential to consider the assumed costs of a dry system.

Dry Doesn't Mean Corrosion-Resistant

Corrosion can flourish in both wet and dry sprinkler systems. While wet systems are permanently charged with static water that is released when the sprinkler activates, the term “dry” system is something of a misnomer, in the sense that this type of fire protection is subject to condensation from the compressed air equipment that charges the pipework in such systems. Unaddressed corrosion can interrupt the system's ability to do its lifesaving work. To address the issue, and because inert nitrogen acts as a drying agent, some facilities opt to replace the atmospheric air of the dry system with a nitrogen generator instead of a compressor. This represents a substantial capital investment for dry systems, as does the routine maintenance needed for systems using compressed air.

Dry Systems Can Have High Installation Costs

Corrosion mitigation is even a part of dry system installation practices. To avoid corrosion, dry sprinkler system piping must be pitched to promote drainage of condensation at its lowest points. The arrangement requires piping to be pitched ½ inch per 10 feet (4 mm/m) for all branch lines, and ¼ inch per 10 feet (2 mm/m) for all other sprinkler piping. This adds to the installed costs of such a system, which also requires auxiliary drains for each pipe section to collect condensates from the pressurized air while minimizing loss of air pressure during maintenance. These systems are also often equipped with heat tracing to provide freeze protection, the cost of which ranges widely. Further, the need for pitched piping presents installation and inspection challenges in smaller facilities or those with complex roof systems. Wet systems do not typically require these accommodations.

Dry Systems Can Have Higher Maintenance Costs

Besides requiring dedicated staff time to inspect and drain, dry pipe sprinkler systems typically require ten additional system components, compared to just four for antifreeze systems. Additionally, maintaining dry systems can be three to four times higher than the initial installed cost, especially if a dry pipe valve has been persistently leaking or the compressor needs excessive repair.

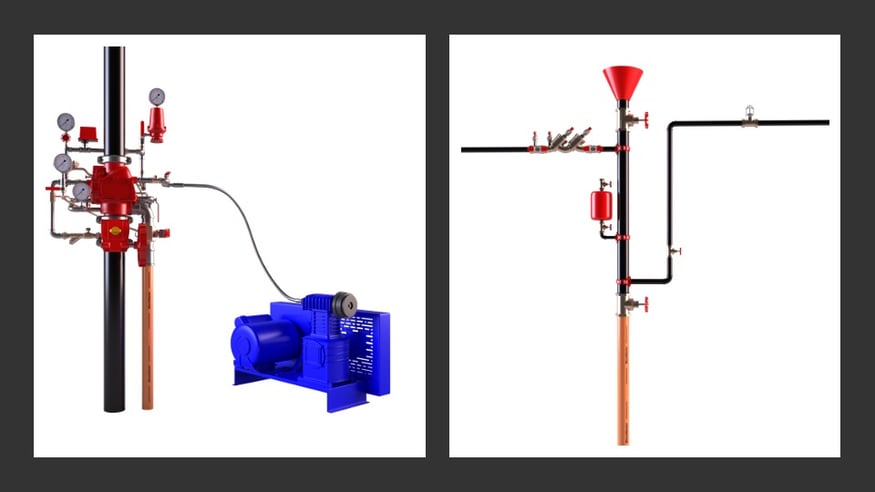

A comparison of a dry system's components (left) against the simpler antifreeze system (right).

freezemaster™ antifreeze Helps Maximize Antifreeze System Benefits

It's rarely worth removing a functioning existing system to take advantage of these benefits. But for new installations or reinstallations, listed antifreeze levels the playing field between dry and wet systems for total ownership costs. And among listed products, freezemaster™ antifreeze can be trusted to meet or exceed all expectations.

freezemaster™ antifreeze is:

- Formulated to meet NFPA 25 requirements

- Factory-premixed

-

Cold temperature protection down to -12ºF (-24ºC)

- Tinted blue for easy identification of a fully flushed and filled system, saving installers from having to constantly test a clear fluid

- UL listed for use with galvanized steel piping, unlike some other brands

-

Equipped with a breakthrough corrosion inhibitor package that effectively reduces pipe corrosion, including MIC, by up to 65%

Once installed, the system's antifreeze requires only annual testing by a qualified inspector. Watch this video to learn more or download the Installation Manual for detailed instructions.